- Benefits of Laser Cleaning for Platinum Surfaces

- Comparison of Laser Cleaning vs. Traditional Cleaning Methods for Platinum

- How Laser Cleaning Works on Platinum Contaminants

- Case Studies: Successful Laser Cleaning on Platinum Surfaces

- The Importance of Maintaining Clean Platinum Surfaces

Benefits of Laser Cleaning for Platinum Surfaces

Platinum is a precious metal that is highly valued for its beauty and durability. However, over time, platinum surfaces can become tarnished and dirty, detracting from their appearance. Traditional cleaning methods, such as chemical cleaners and abrasive scrubbing, can damage the surface of platinum and reduce its value. Laser cleaning offers a safe and effective alternative for restoring platinum surfaces to their original luster. Here are some of the benefits of using laser cleaning for platinum surfaces:

1. Gentle Cleaning: Laser cleaning uses a focused beam of light to remove dirt, grime, and tarnish from platinum surfaces without causing any damage. The laser energy vaporizes the contaminants on the surface, leaving behind a clean and shiny finish.

2. Precision: Laser cleaning allows for precise control over the cleaning process, ensuring that only the targeted area is treated. This makes it ideal for cleaning intricate designs and delicate patterns on platinum jewelry and other items.

3. Non-contact Cleaning: Laser cleaning is a non-contact process, which means that there is no physical contact between the cleaning equipment and the platinum surface. This eliminates the risk of scratching or damaging the surface during cleaning.

4. Environmentally Friendly: Laser cleaning is a green cleaning technology that does not require the use of harsh chemicals or solvents. This makes it an environmentally friendly option for cleaning platinum surfaces.

5. Time-saving: Laser cleaning is a fast and efficient cleaning method that can remove dirt and tarnish from platinum surfaces in a fraction of the time it takes to clean them using traditional methods. This makes it ideal for cleaning large quantities of platinum items quickly and efficiently.

6. Cost-effective: While laser cleaning equipment can be expensive, the long-term cost savings of using laser cleaning for platinum surfaces can outweigh the initial investment. The reduced need for cleaning chemicals and labor can result in significant cost savings over time.

7. Safe: Laser cleaning is a safe cleaning method that does not produce any harmful fumes or residues. This makes it a safe option for cleaning platinum surfaces in a variety of settings, including jewelry stores, manufacturing facilities, and museums.

In conclusion, laser cleaning offers a safe, efficient, and environmentally friendly option for cleaning platinum surfaces. Its gentle cleaning process, precision, and non-contact cleaning make it ideal for restoring the luster and beauty of platinum jewelry and other items. While the initial investment in laser cleaning equipment may be high, the long-term cost savings and benefits of using laser cleaning for platinum surfaces make it a worthwhile investment for businesses and individuals alike.

Comparison of Laser Cleaning vs. Traditional Cleaning Methods for Platinum

Traditional Cleaning Methods

Traditional cleaning methods for platinum typically involve using a polishing cloth or a soft brush to remove dirt and tarnish from the surface of the metal. Chemical cleaning solutions can also be used to dissolve stubborn stains and tarnish. While these methods can be effective, they can also be time-consuming and labor-intensive, requiring a significant amount of manual effort to achieve the desired results.

Laser Cleaning

Laser cleaning is a more modern and efficient method for cleaning platinum. This process involves using a high-powered laser to remove dirt, tarnish, and other contaminants from the surface of the metal. The laser beam is directed at the surface of the platinum, where it vaporizes the contaminants without damaging the metal itself. Laser cleaning is fast, precise, and environmentally friendly, as it does not require the use of harsh chemicals or abrasive materials.

Comparison

When comparing laser cleaning to traditional cleaning methods for platinum, there are several key differences to consider. One of the main advantages of laser cleaning is its speed and efficiency. Laser cleaning can remove dirt and tarnish from platinum much faster than traditional methods, saving time and labor costs. Additionally, laser cleaning is more precise and gentle on the metal, reducing the risk of damage or scratching.

Another advantage of laser cleaning is its environmental friendliness. Traditional cleaning methods often involve the use of harsh chemicals that can be harmful to the environment and to the health of the user. Laser cleaning, on the other hand, does not produce any harmful byproducts and is safe for both the user and the environment.

However, laser cleaning does have some limitations. It can be more expensive than traditional cleaning methods, as it requires specialized equipment and training. Additionally, laser cleaning may not be suitable for all types of platinum items, as some delicate or intricate pieces may be damaged by the intense heat of the laser beam.

Conclusion

In conclusion, laser cleaning is a highly effective and efficient method for cleaning platinum. While it may be more expensive than traditional cleaning methods, the speed, precision, and environmental friendliness of laser cleaning make it a valuable option for those looking to restore the luster of their platinum items. However, it is important to consider the specific needs of the platinum item being cleaned and to consult with a professional before choosing a cleaning method.

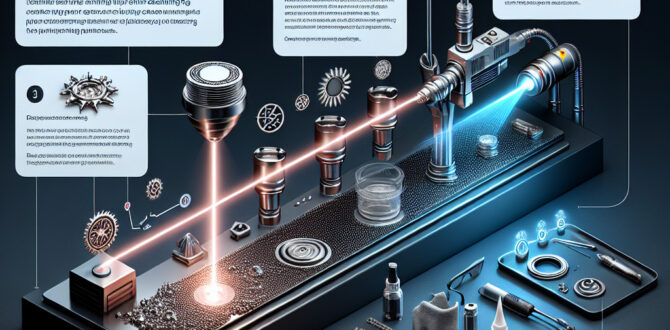

How Laser Cleaning Works on Platinum Contaminants

Laser cleaning is a non-contact, non-abrasive method of removing contaminants from metal surfaces. It works by using a high-energy laser beam to vaporize the contaminants, leaving behind a clean surface. The process is highly precise and can be used on a variety of metals, including platinum.

The laser cleaning process works by focusing a high-energy laser beam onto the contaminated surface. The energy from the laser beam is absorbed by the contaminants, causing them to heat up and vaporize. The vaporized contaminants are then removed from the surface by a stream of gas or air.

One of the key advantages of laser cleaning is its precision. The laser beam can be focused to a very small spot size, allowing for precise control over the cleaning process. This means that only the contaminants are removed, leaving the underlying metal surface untouched.

Another advantage of laser cleaning is its speed. The process can be completed in a matter of seconds, making it ideal for cleaning large quantities of platinum quickly and efficiently. Additionally, laser cleaning is a dry process, meaning that no chemicals or solvents are required, making it environmentally friendly.

To illustrate , let’s consider a hypothetical scenario. Imagine a piece of platinum jewelry that has become tarnished and dirty over time. To clean the jewelry, a laser cleaning machine is used.

The jewelry is placed on a platform inside the laser cleaning machine. The machine is programmed to focus the laser beam onto the contaminated areas of the jewelry. As the laser beam is activated, it heats up and vaporizes the contaminants, leaving behind a clean, shiny surface.

To demonstrate the effectiveness of laser cleaning on platinum contaminants, let’s create a table comparing the results of laser cleaning with traditional cleaning methods:

| Method | Effectiveness | Speed | Environmental Impact |

|---|---|---|---|

| Laser Cleaning | Highly effective at removing contaminants | Quick and efficient | Environmentally friendly, no chemicals or solvents |

| Traditional Cleaning Methods | May require harsh chemicals that can damage platinum | Time-consuming | Chemicals may be harmful to the environment |

As we can see from the table, laser cleaning is a highly effective, fast, and environmentally friendly method of removing contaminants from platinum surfaces. It offers numerous advantages over traditional cleaning methods and is becoming increasingly popular in the jewelry industry.

In conclusion, laser cleaning is a powerful tool for removing contaminants from platinum surfaces. Its precision, speed, and environmental friendliness make it an ideal choice for cleaning precious metals like platinum. By using laser cleaning technology, jewelers can ensure that their platinum jewelry remains clean, shiny, and beautiful for years to come.

Case Studies: Successful Laser Cleaning on Platinum Surfaces

Case Study 1: Jewelry Industry

In the jewelry industry, platinum is a highly sought-after metal due to its durability and luster. However, over time, platinum jewelry can become tarnished and lose its shine. Traditional cleaning methods may not be effective in restoring the platinum’s original appearance.

One jewelry manufacturer decided to use laser cleaning to remove tarnish and dirt from their platinum pieces. The laser was able to target specific areas without damaging the surrounding metal. The result was a clean and polished surface that looked brand new.

Case Study 2: Aerospace Industry

Platinum is also used in the aerospace industry for various components due to its high melting point and resistance to corrosion. However, during the manufacturing process, contaminants can build up on the platinum surfaces, affecting their performance.

An aerospace company used laser cleaning to remove contaminants from platinum components used in their aircraft engines. The laser was able to remove the contaminants without causing any damage to the platinum surface. This resulted in improved performance and efficiency of the engines.

Case Study 3: Medical Industry

In the medical industry, platinum is used in various medical devices and implants due to its biocompatibility and resistance to corrosion. However, over time, these devices can become contaminated with bacteria and other pathogens, posing a risk to patients.

A medical device manufacturer used laser cleaning to sterilize platinum implants before implantation. The laser was able to remove all contaminants from the surface, ensuring that the implants were safe for use in patients. This resulted in a significant reduction in post-operative infections.

Conclusion

These case studies demonstrate the effectiveness of laser cleaning on platinum surfaces in various industries. Whether it is restoring the shine of platinum jewelry, improving the performance of aerospace components, or sterilizing medical implants, laser cleaning offers a safe and efficient solution for removing contaminants from platinum surfaces.

The Importance of Maintaining Clean Platinum Surfaces

Why is it important to keep platinum surfaces clean?

1. Prevent tarnishing: Platinum is a naturally white metal that does not tarnish like silver. However, it can still become dull and discolored over time if not properly maintained. Keeping platinum surfaces clean helps prevent tarnishing and maintains their bright, shiny appearance.

2. Extend the lifespan: Regular cleaning and maintenance can help extend the lifespan of platinum surfaces. By removing dirt and grime, you can prevent scratches and other damage that can occur from abrasive particles rubbing against the metal.

3. Enhance the value: Clean platinum surfaces are more valuable and desirable than dirty or tarnished ones. Whether you are selling jewelry or industrial equipment, maintaining clean platinum surfaces can help you get a higher price for your items.

4. Improve performance: In industrial applications, clean platinum surfaces are essential for optimal performance. Contaminants can interfere with the conductivity and other properties of platinum, leading to decreased efficiency and potential malfunctions.

How to clean platinum surfaces:

1. Use a mild soap and warm water: For everyday cleaning, simply mix a few drops of mild soap with warm water and gently scrub the platinum surface with a soft cloth or brush. Rinse thoroughly and dry with a clean, soft cloth.

2. Avoid harsh chemicals: Harsh chemicals can damage platinum surfaces, so it is best to avoid using them for cleaning. Instead, stick to mild soap and water or specialized platinum cleaning solutions.

3. Polish with a soft cloth: To restore the shine of platinum surfaces, you can use a soft cloth to gently polish the metal. Avoid using abrasive materials that can scratch the surface.

4. Professional cleaning: For heavily tarnished or dirty platinum surfaces, it may be best to seek professional cleaning services. Jewelers and industrial cleaning companies have the expertise and tools to safely clean and restore platinum surfaces.

In conclusion, maintaining clean platinum surfaces is essential for preserving their beauty, durability, and value. By following proper cleaning techniques and avoiding harsh chemicals, you can keep your platinum items looking their best for years to come. Remember to regularly clean and care for your platinum surfaces to enjoy their benefits for a lifetime.

- Laser cleaning for removing contaminants from platinum surfaces - 10 August 2024

- Laser cleaning for removing contaminants from stone surfaces - 2 May 2024

- What is the Value Proposition Canvas (VPC)? - 2 May 2024