- Types of contaminants on paper surfaces

- Benefits of laser cleaning for paper conservation

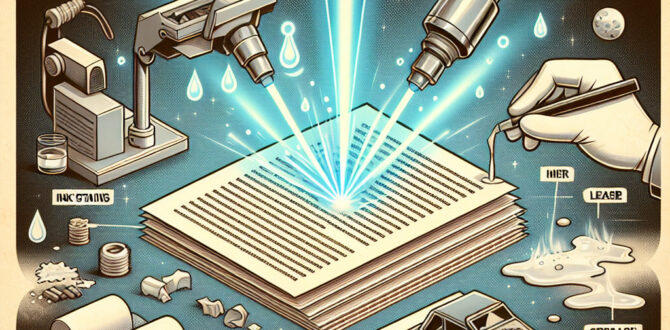

- Comparison of laser cleaning with traditional cleaning methods

- Laser cleaning for removing grease and oil from paper surfaces

- Laser cleaning for removing smoke damage from paper surfaces

- Laser cleaning for removing graffiti from paper surfaces

- Laser cleaning for removing sizing and coatings from paper surfaces

- Laser cleaning for removing sizing and coatings from paper surfaces

Types of contaminants on paper surfaces

1. Dust and dirt

Dust and dirt are common contaminants that can accumulate on paper surfaces during storage or handling. These particles can cause smudges and streaks on printed materials, affecting the overall appearance of the final product. To prevent dust and dirt contamination, it is important to store paper in a clean and dry environment and handle it with care to minimize contact with dirty surfaces.

2. Ink residue

Ink residue is another common contaminant that can be found on paper surfaces, especially in printing environments. This residue can build up on printing equipment and transfer onto paper during the printing process, leading to smudges and poor print quality. Regular cleaning and maintenance of printing equipment is essential for preventing ink residue contamination.

3. Oil and grease

Oil and grease can also contaminate paper surfaces, leaving behind unsightly stains and marks. These contaminants can come from a variety of sources, including machinery, hands, and food. To prevent oil and grease contamination, it is important to handle paper with clean hands and avoid placing oily or greasy objects on paper surfaces.

4. Water damage

Water damage is a serious contaminant that can cause paper to warp, wrinkle, or even disintegrate. Exposure to moisture can weaken the fibers in paper, leading to irreversible damage. To prevent water damage, it is important to store paper in a dry environment and avoid exposing it to water or high humidity levels.

5. Chemical residues

Chemical residues from cleaning products, adhesives, or other sources can also contaminate paper surfaces. These residues can cause discoloration, staining, or other damage to paper products. To prevent chemical contamination, it is important to use non-toxic cleaning products and avoid exposing paper to harmful chemicals.

6. Mold and mildew

Mold and mildew are common contaminants that can grow on paper surfaces in damp or humid environments. These contaminants can cause discoloration, odor, and deterioration of paper products. To prevent mold and mildew contamination, it is important to store paper in a dry and well-ventilated environment and address any moisture issues promptly.

7. Foreign particles

Foreign particles such as hair, fibers, or debris can also contaminate paper surfaces, causing blemishes or imperfections in printed materials. To prevent foreign particle contamination, it is important to keep work areas clean and free of clutter, and to handle paper with care to avoid contact with foreign objects.

Conclusion

Contaminants on paper surfaces can have a detrimental impact on the quality of printed materials. By understanding the different types of contaminants and implementing strategies to prevent them, it is possible to maintain the integrity of paper products and ensure high-quality printing results.

#contaminants #paper #surfaces #dust #dirt #ink #residue #oil #grease #water #damage #chemical #residues #mold #mildew #foreign #particles

Types of contaminants on paper surfaces, common contaminants, prevent contamination, paper products, printing materials, dust and dirt, ink residue, oil and grease, water damage, chemical residues, mold and mildew, foreign particles, high-quality printing.

Benefits of laser cleaning for paper conservation

- Non-invasive: Laser cleaning does not require any physical contact with the paper, reducing the risk of damage to the artifact.

- Precision: Laser cleaning can target specific areas of dirt or discoloration with pinpoint accuracy, ensuring that only the affected areas are treated.

- Gentle: The controlled heat and energy of the laser ensure that the paper is not subjected to harsh chemicals or abrasive materials, preserving its integrity.

- Efficient: Laser cleaning is a fast and efficient process, allowing conservators to clean large quantities of paper artifacts in a relatively short amount of time.

- Environmentally friendly: Laser cleaning does not produce any harmful byproducts or waste, making it a sustainable choice for paper conservation.

Overall, laser cleaning offers a safe, effective, and environmentally friendly solution for preserving and restoring paper artifacts. Its non-invasive nature and precision make it an ideal choice for conservators looking to clean and protect valuable paper documents and artworks.

By embracing this innovative technology, conservators can ensure that future generations will be able to enjoy these important pieces of history for years to come.

Hashtags: #laser #cleaning #paper #conservation

Keywords: laser cleaning, paper conservation, non-invasive, precision, gentle, efficient, environmentally friendly

Long-tail phrases: benefits of laser cleaning for paper conservation, laser cleaning for delicate paper artifacts, non-invasive cleaning technology for paper preservation

Comparison of laser cleaning with traditional cleaning methods

Traditional cleaning methods:

– Scrubbing with brushes or sponges

– Using chemical solvents

– High-pressure water blasting

– Sandblasting

Laser cleaning:

– Uses a high-powered laser beam to remove contaminants

– Non-contact method, reducing the risk of damage to the surface

– Environmentally friendly, as it does not require the use of chemicals

– Can be used on a variety of surfaces, including metal, plastic, and glass

Comparison:

– Efficiency: Laser cleaning is faster and more precise than traditional methods.

– Cost: While the initial investment in a laser cleaning system may be higher, the long-term cost savings can be significant.

– Safety: Laser cleaning eliminates the need for harsh chemicals and reduces the risk of injury to workers.

– Versatility: Laser cleaning can be used on a wider range of surfaces and materials.

In conclusion, laser cleaning is a superior alternative to traditional cleaning methods in terms of efficiency, cost, safety, and versatility. As technology continues to advance, we can expect to see an increase in the use of laser cleaning in various industries.

#laser #cleaning #technology #efficiency #costs #safety #versatility

long-tail phrases: laser cleaning vs traditional methods, benefits of laser cleaning, laser cleaning applications in industry.

Laser cleaning for removing grease and oil from paper surfaces

One of the key advantages of laser cleaning is its precision. The laser beam can be focused to a very small spot size, allowing for targeted cleaning of specific areas without affecting the surrounding material. This makes it ideal for removing grease and oil stains from delicate paper surfaces without causing any damage.

Another benefit of laser cleaning is its efficiency. Traditional cleaning methods such as solvents or abrasive cleaners can be time-consuming and labor-intensive, whereas laser cleaning is a quick and effective solution for removing grease and oil stains from paper surfaces.

Furthermore, laser cleaning is a safe and environmentally friendly method of cleaning. Unlike traditional cleaning methods that may involve harsh chemicals or solvents, laser cleaning does not produce any harmful by-products or waste, making it a sustainable option for removing contaminants from paper surfaces.

In conclusion, laser cleaning is a highly effective method for removing grease and oil stains from paper surfaces. Its precision, efficiency, and environmental friendliness make it a superior alternative to traditional cleaning methods. Whether in industrial settings or for personal use, laser cleaning offers a safe and efficient solution for keeping paper surfaces clean and free of contaminants.

- precision

- efficiency

- environmentally friendly

- non-contact

- targeted cleaning

- laser cleaning for removing grease and oil from paper surfaces

- precision cleaning technology for paper surfaces

- environmentally friendly cleaning method

- efficient removal of contaminants from paper

- safe and effective cleaning solution

#laser #cleaning #grease #oil #paper #surfaces #precision #efficiency #environmentallyfriendly #noncontact #targetedcleaning #safecleaning #cleaningsolution

Laser cleaning for removing smoke damage from paper surfaces

This process is particularly useful for removing smoke damage from historical documents, artwork, and other valuable paper items. Laser cleaning is gentle enough to preserve the integrity of the paper while still effectively removing the smoke residue.

One of the key advantages of laser cleaning is its precision. The laser can be adjusted to target specific areas of smoke damage, allowing for a controlled and thorough cleaning process. Additionally, laser cleaning is a dry process, meaning that there is no risk of water damage to the paper.

Laser cleaning is also environmentally friendly, as it does not require the use of harsh chemicals or solvents. This makes it a safe and sustainable option for cleaning smoke-damaged paper surfaces.

Overall, laser cleaning is a highly effective and efficient method for removing smoke damage from paper surfaces. Its non-invasive nature and precision make it an ideal choice for preserving and restoring valuable paper items.

Keywords:

- Laser cleaning

- Smoke damage

- Paper surfaces

- Historical documents

- Artwork

Long-tail phrases:

- Non-invasive solution for removing smoke damage

- Gentle cleaning process for delicate paper

- Environmentally friendly and sustainable cleaning method

#laser #cleaning #smokedamage #papersurfaces #historicaldocuments #artwork #noninvasivesolution #gentlecleaningprocess #environmentallyfriendly #sustainablecleaningmethod

Laser cleaning for removing graffiti from paper surfaces

How Does Laser Cleaning Work?

Laser cleaning works by using a high-energy laser beam to vaporize the graffiti particles on the paper surface. The laser beam is directed at the graffiti, causing it to heat up and evaporate without damaging the paper underneath. The process is highly controlled and can be adjusted to remove graffiti of varying thickness and composition.

Benefits of Laser Cleaning for Removing Graffiti

There are several benefits to using laser cleaning for removing graffiti from paper surfaces:

| Benefits | Description |

|---|---|

| Non-contact | Laser cleaning is a non-contact method, which means there is no physical contact with the paper surface. This reduces the risk of damage to the paper and ensures a precise cleaning process. |

| Precise | Laser cleaning allows for precise control over the cleaning process, making it suitable for delicate paper surfaces. The laser beam can be adjusted to target specific areas of graffiti without affecting the surrounding paper. |

| Environmentally friendly | Laser cleaning does not require the use of chemicals or abrasive materials, making it an environmentally friendly graffiti removal method. It also produces minimal waste and does not release harmful fumes into the air. |

Applications of Laser Cleaning for Removing Graffiti

Laser cleaning can be used for removing graffiti from a variety of paper surfaces, including posters, books, and historical documents. It is also suitable for removing graffiti from delicate artworks and manuscripts without causing any damage.

Conclusion

Laser cleaning offers a safe, precise, and environmentally friendly solution for removing graffiti from paper surfaces. Its non-contact nature and precise control make it an ideal method for preserving delicate paper materials while effectively removing graffiti.

#laser #cleaning #graffiti #paper #surfaces #non-contact #precise #environmentally friendly #applications #delicate materials

frazy kluczowe:

– safe and effective graffiti removal

– precise control over cleaning process

– environmentally friendly solution for delicate materials

Laser cleaning for removing sizing and coatings from paper surfaces

Laser cleaning works by using a high-powered laser beam to vaporize the sizing and coatings on the surface of the paper. The laser beam is directed at the specific areas that need to be cleaned, and the intense heat generated by the laser vaporizes the unwanted materials without damaging the paper underneath. This process is highly precise and can be controlled to remove only the desired materials, leaving the paper surface clean and undamaged.

The benefits of laser cleaning

There are many benefits to using laser cleaning for removing sizing and coatings from paper surfaces. One of the main advantages is the precision of the process, which allows for targeted cleaning without damaging the paper itself. Laser cleaning is also environmentally friendly, as it does not require the use of harsh chemicals or abrasive methods that can be harmful to the environment. Additionally, laser cleaning is a fast and efficient process that can save time and money compared to traditional cleaning methods.

Applications of laser cleaning

Laser cleaning can be used in a variety of applications, including the restoration of historical documents and artworks, the cleaning of industrial machinery and equipment, and the removal of graffiti from public spaces. The versatility of laser cleaning makes it a valuable tool for a wide range of industries and applications.

Conclusion

Laser cleaning is a cutting-edge technology that offers a precise, gentle, and environmentally friendly alternative to traditional methods of removing sizing and coatings from paper surfaces. With its many benefits and applications, laser cleaning is revolutionizing the way we clean and restore paper surfaces.

- precision

- environmentally friendly

- fast and efficient

- versatile

- cutting-edge technology

- historical documents

- industrial machinery

- graffiti removal

#laser #cleaning #paper #sizing #coatings #precision #environmentallyfriendly #cuttingedgetechnology #historicaldocuments #industrialmachinery #graffitiremoval

Laser cleaning for removing sizing and coatings from paper surfaces

One of the key advantages of laser cleaning is its precision. The intensity and duration of the laser beam can be adjusted to target specific contaminants while leaving the rest of the surface untouched. This level of control allows conservators to remove unwanted sizing and coatings without affecting the integrity of the paper.

Another benefit of laser cleaning is its versatility. It can be used on a wide range of paper surfaces, including parchment, vellum, and modern paper. This makes it an ideal solution for conservators working with a variety of materials.

Overall, laser cleaning offers a gentle and effective way to remove sizing and coatings from paper surfaces, making it a valuable tool for conservators and restoration experts.

Keywords:

- Laser cleaning

- Historical documents

- Artworks

- Manuscripts

- Conservation

- Restoration

Long-tail phrases:

- Laser cleaning for delicate paper surfaces

- Non-contact cleaning method for historical documents

- Preserving paper artifacts with laser technology

#laser #cleaning #paper #sizing #coatings #conservation #restoration #historicaldocuments #artworks #manuscripts #delicatepapersurfaces #noncontactcleaning #preservation #artifacts #technology

- Laser cleaning for removing contaminants from platinum surfaces - 10 August 2024

- Laser cleaning for removing contaminants from stone surfaces - 2 May 2024

- What is the Value Proposition Canvas (VPC)? - 2 May 2024